Alulibs

Real-time monitoring for molten aluminum composition

Increase the efficiency of your aluminum alloying process

Talk to an expertReal-time chemistry monitoring

Faster into specification

Better use of material

Independent from the lab

Reduce sampling

Easy plant interface

The Alulibs advantage

Multi-element analyzer

The Alulibs is the only online multi-element analyzer for molten aluminum.

Whatever your process, the Alulibs details information on all the elements you need to track. Why limit yourself to one element when you can benefit from so many more?

Long-term tracking of aluminum alloy composition

Tracking changes in aluminum alloy composition is critical to controlling the quality of aluminum ingot manufactured and to increasing plant productivity. The Alulibs enables operators and plant managers to view long-term trends to better monitor alloy transition.

For example, a three-day trend demonstrates tracking an alloy change that required an increased concentration of Silicon. Comparing the lab data, represented by circles, to the continuous measurements of Alulibs (line data), it’s clear that the Alulibs is more stable than the lab data, which often produce abnormal results due to sampling inconsistencies.

Easy calibration

The Alulibs comes with pre-defined calibration curves for the entire specified element ranges. These calibration curves have been developed by Tecnar to alleviate the need for a sampling campaign that requires samples at different concentrations.

These pre-defined calibration curves allow the user to adjust the entire calibration with a single sample check.

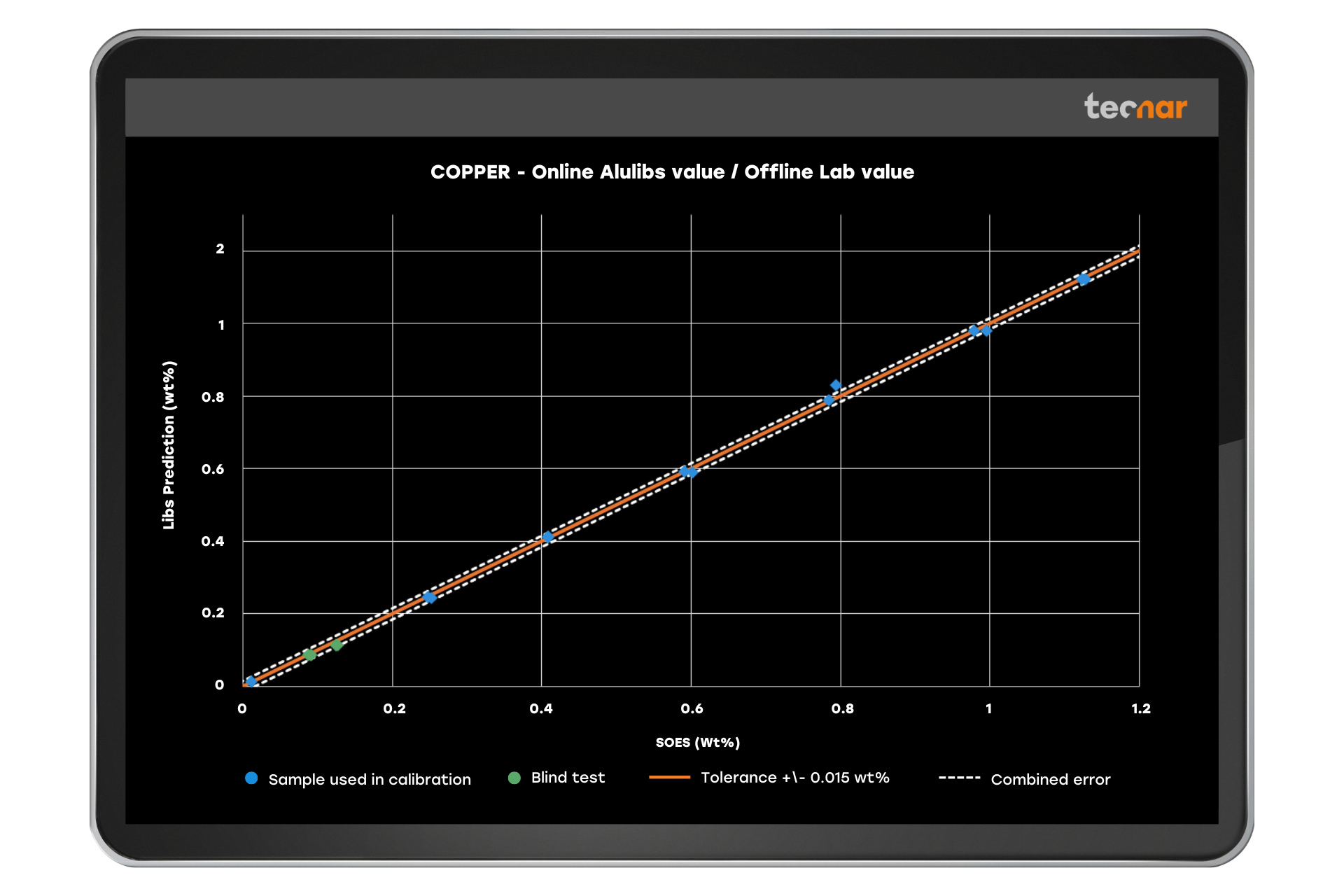

Proven data you can trust

Overall, 12 elements were successfully tested and predicted in Al6000 series blind experiments.

For example, blind experiment results for a copper concentration range in an Al6000 series alloy have demonstrated the high accuracy of the Alulibs. The experiment was performed in a 20-kg crucible with two melts. The first melt’s known concentrations established a calibration (blue dots), while the second had unknown concentrations (green dots). Both melts were verified using SOES laboratory equipment.

Results from the copper demonstration confirmed the Alulibs’ high accuracy with a combined standard deviation of 0.0075 wt%, a relative standard deviation of 0.9%, and a maximum relative measurement error of 1.8% with a 95% confidence interval.

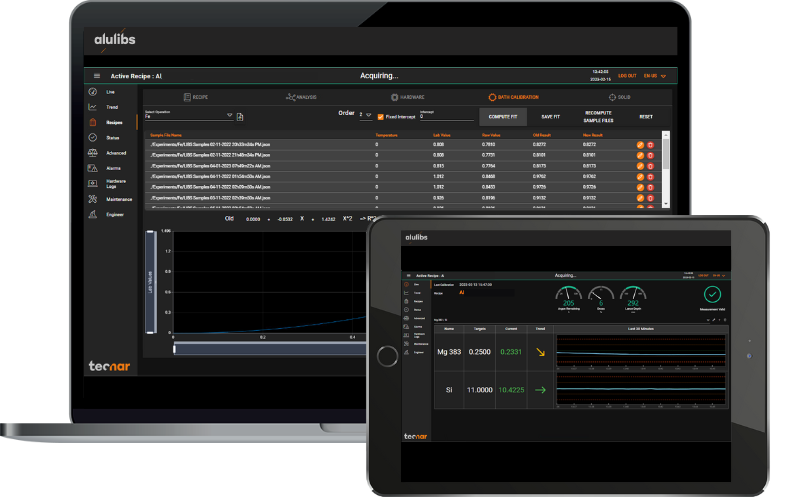

Intuitive software

You’re in control with the Alulibs. It features a modern, web-based user interface, making it easy to access from any computer, anywhere. What’s more, the interface can be viewed on multiple viewing devices simultaneously. Communication infrastructure via HTTP or external PLC makes full 4.0 booth integration possible.

Development and implementation of LIBS analyzer for liquid aluminum analysis

In 2006, Tecnar teamed up with the Canadian National Research Council and Alcoa to develop a hot metal LIBS (Laser-Induced Breakdown Spectroscopy) analyzer for liquid aluminum. In 2019, Galvalibs 2.0 became the new standard for liquid zinc composition analysis, so Tecnar refocused on aluminum. Working with partners like Audubon, Novelis and Constellium, new laboratory trials were conducted using the latest Galvalibs platform to verify its sensitivity, accuracy, reproducibility and range. In spring 2020, a permanent installation was completed at an Audubon plant to test the instrument’s long-term stability. Today, the instrument has proven to be highly durable and reliable in harsh environments.

Interested in real-time molten aluminum composition monitoring?

Leave your details so our experts can contact you.

Our team will answer all your questions and suggest the best solution for your needs.