Substitute ICP-OES laboratory equipment with Tecnar's in-line analyzers for molten metal composition analysis

The ultimate molten metal monitoring solution to increase your quality and stay competitive in today’s industry

Talk to an expertWhy use Tecnar's analyzers?

No more sampling molten metal

Increase operational uptime and conformity to industrial and client-specific standards.

Continuous real-time data

24/7 live measurements fast track operations.

Highest real-time accuracy

Novel technology with a proven accuracy of 0.5% RSD.

Multi-element analyzer

Whatever your process, Tecnar’s analyzer provides information on all the elements you need to track.

Low consumable

Designed to be a very low-consumable and worry-free operation analyzer.

Less reliant on ICP-OES laboratory equipment

Reduce laboratory operating and capital expenditures with LIBS analyzers.

Discover the Galvalibs

Achieve high-quality galvanized coil

Produce top-quality coils, time after time, by always knowing your bath dynamics. The Galvalibs 2.0 gives your operator the power to quickly adjust to bath conditions, maintain the proper chemistry, stabilize the bath level and verify cleanliness for optimal operating conditions.

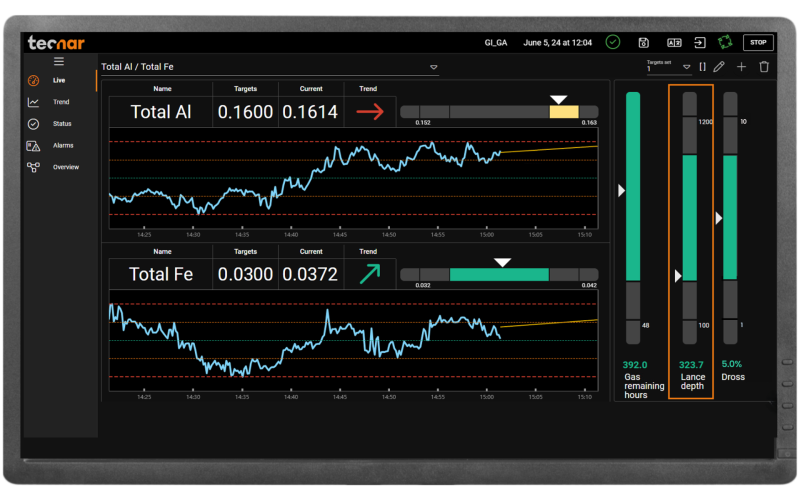

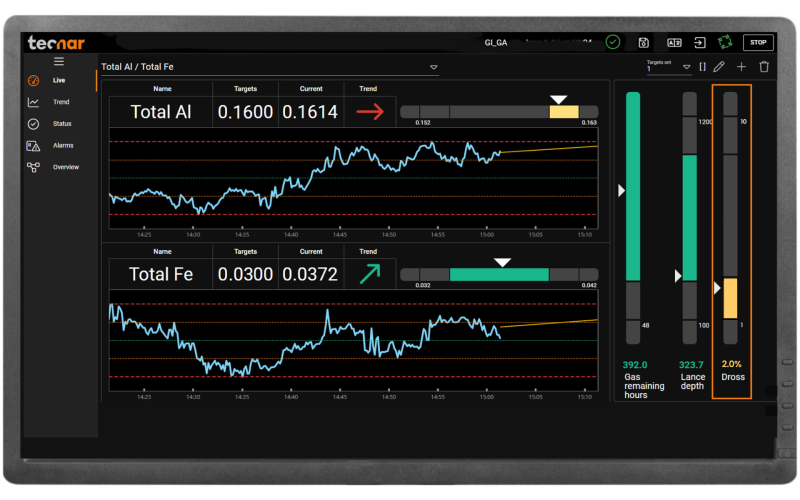

Real-time and accurate bath composition

The Galvalibs 2.0 gives you access to real-time, accurate multi-element bath composition.

Most accurate bath level in the industry

Get the galvanizing industry’s most precise and accurate bath level.

Better dross control

Monitors the dross level of the galvanizing bath in real-time.

Galvalibs equipment

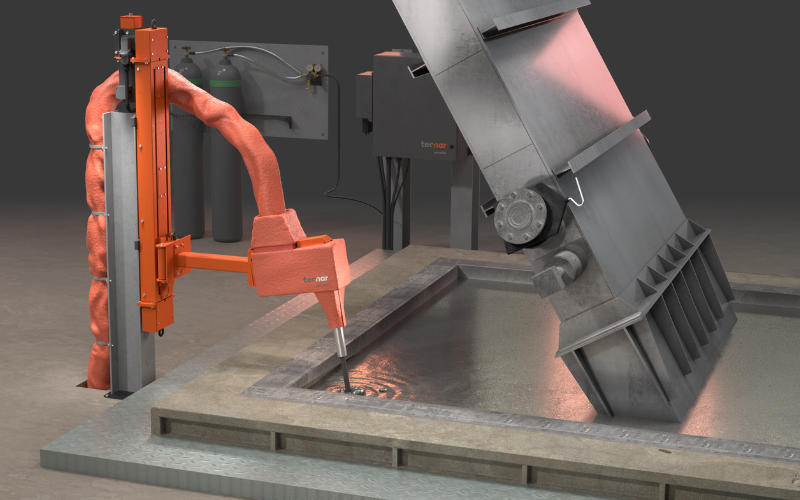

The Galvalibs 2.0 is designed for the daily reality of a continuous hot-dip galvanizing line. It comes in a robust, compact and low-maintenance package.

Self-calibration

With the Galvalibs Calibration Unit (GCU), operators can perform routine calibrations without a laboratory.

Easy self-installation

The Galvalibs is a self-installed system.

Discover the Alulibs

The goal of the aluminum industry is to optimize the use of alloy materials, and they do so by consistently sampling their molten metal.

The Alulibs automates sampling by providing continuous automated multiple-element tracking. Live measurements of the alloy composition before additions prevent excessive use of critical elements.

In-line monitoring of molten aluminum composition

Optimize your aluminum alloying process with Alulibs.

Alulibs equipment

The Alulibs is designed for the daily reality of an aluminum smelter. It comes in a robust, compact and low-maintenance package.

Easy self-installation

The Alulibs is a self-installed system.

About Tecnar

Tecnar knows that better process control means increased productivity. That’s why your productivity is at the heart of everything we do. Tecnar designs and develops advanced sensors for industrial process monitoring and control.

Founded in 1989 as a spin-off from Canada’s National Research Council, Tecnar has since diversified into four distinct product lines that share a common goal: To make a difference in the daily life of its clients by integrating its technology and know-how.

Interested in getting into molten-metal chemistry?

Our team will answer all your questions and suggest the best solution for your needs.

Leave your details so our experts can contact you.