Alulibs

All-in-one analyzer for molten aluminum chemistry

Alulibs brings the laboratory to the line by laser sampling the molten aluminum, yielding a highly accurate chemistry analysis in real time.

Talk to an expertAll-in-one

analyzer

Alulibs’ patented technology, based on real-time Laser-Induced Breakdown Spectroscopy (LIBS), performs a laser sampling of the molten metal, deep below the surface, yielding a highly accurate, multi-element chemical analysis. By its nature, dissolved concentrations are measured directly without the need for model-based calculation.

Probe

This compact all-inclusive analyzer is ready for operation in harsh environments. The Alulibs has been designed with the operator in mind. Lightweight and easy to connect and disconnect for no-hassle manipulation.

- DuraBeam™ sealed optics

- Easy to mount and connect, can be manipulated by a single operator

- Compressed air cooling system

- Protective silicone/fibreglass thermal blanket also acts as a splash guard

- Easy replaceable sacrificial output window.

Lance

Sturdy hollow ceramic cylinder for inserting probing gas bubbles deep into the molten aluminum. One lance is used for many years.

- Chemically inert to molten aluminum

- Robust dense ceramic cylinder

- Easily sustain high-temperature melt

- Easy “twist-lock” attachment for quick-change or maintenance.

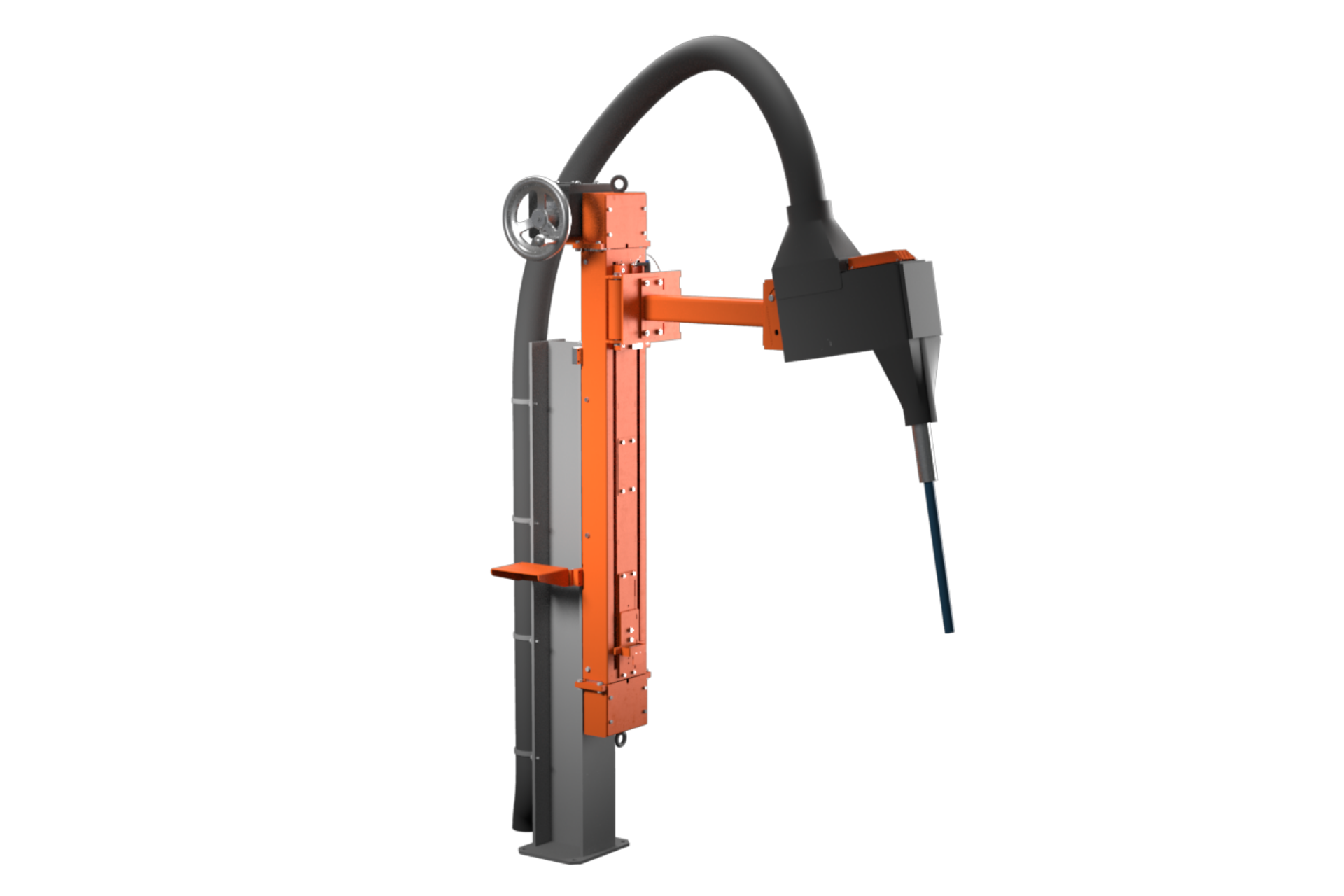

Motorized positioning device

Easily insert and extract the probe from the molten aluminum. The device automatically positions the probe near the surface, before insertion to allow moisture removal and thermal balancing of the lance. The motorized positioning device makes operation easy.

- Industrial-grade motorized positioning device to slowly insert lance in melt

- Three positions: in melt, idle above melt, in maintenance

- Equipped with safety interlocks

- Accurate in-melt position with precision better than 1 mm

- Automated melt insertion sequence, ensuring proper lance drying and surface skimming

- Very low maintenance

- Customizable travel and extension over melt.

Manual positioning device

Easily insert and extract the probe from the molten aluminum. Low-cost alternative to the motorized positioning device.

- Industrial-grade manual positioning device to slowly insert lance in melt

- Three positions: in melt, idle above melt, in maintenance

- Equipped with safety interlocks

- Accurate in-melt position with precision better than 1 mm

- Very low maintenance

- Customizable travel and extension over melt.

Control unit

Robust industrial-grade control unit for easy access to data and status of the analyzer.

- Small footprint

- Can be located up to 40 metres (120 ft.) from analyzer and melt

- PLC-based automation and controls

- Passively cooled

- Sealed enclosure to industrial environment (IP 54).

Gas supply management

Keep your data unbiased and your lance clean with Tecnar’s specifically designed gas supply system. The flexible stainless steel line prevents impurities from reaching the measurement environment.

- Double-stage, high-purity regulator

- Leak-proof stainless steel flexible delivery tube

- Dual pigtail inlets for uninterrupted gas supply when changing cylinder

- Automated flow control to minimize gas consumption, especially when analyzer is idle

- Bottle pressure monitoring to know when to replace cylinder.

Plant interface

Get your data anywhere at any time with an Alulibs interface with your plant network.

- Fully automated data transfer to plant network or level 2 for feedback loop

- Direct access to PLC block data readout

- TCP/IP continuous streaming of all data recorded by analyzer

- Up to 10 analog outputs available – standard 2 outputs

- Tecnar UI

- Lifetime operation license and upgrade.

Technical specifications - Alulibs

Chemistry

Element concentration range

Silicon (Si) 0.03 - 17%

Iron (Fe) 0.02 - 3%

Copper (Cu) 0.01 - 5%

Manganese (Mn) 0.01 - 2%

Magnesium (Mg) 0.01 - 3%

Chromium (Cr) 0.03 - 2%

Nickel (Ni) 0.01 - 2%

Zinc (Zn) 0.05 - 4 %

Titanium (Ti) 0.005 - 2%

Lead (Pb) 0.001 - 2 %

Zirconium (Zr) 0.005 - 2%

Vanadium (V) 0.005 - 2%

Utilities

Electrical supply

200 - 240 VAC @ 50 or 60 Hz, -5%/+10%, 4 to 7 Amp

Compressed air supply

Instrument-compressed air (ANSI/ISA-7.0.01), 550 kPa, 42.5 to 68 m³/hr

Instrument-compressed air (ANSI/ISA-7.0.01), 80 psi, 25 to 40 cfm

Gas supply

Argon quality: minimum gas purity 4.8 (99.998%) Average consumption: 1.0 LPM

Dimensions and weight

Probe (without lance)

499 mm x 338 mm x 141 mm

21 kg

20 in. x 13 in. x 5.6 in.

45 lbs.

Lance

111 mm x 83 mm x 821 mm

4 kg

4.4 in. x 3.3 in. x 32.3 in.

9 lbs.

Motorized positioning device

1795 mm x 444 mm x 852 mm

110 kg

Standard extension - 450 mm

Standard travel range - 900 mm

70.7 in. x 17.5 in. x 33.5 in.

243 lbs.

Standard extension - 17.7 in.

Standard travel range - 35.4 in.

Manual positioning device

1769 mm x 512 mm x 852 mm

100 kg

Standard extension - 450 mm

Standard travel range - 900 mm

69.6 in. x 20.2 in. x “33.5 in.

220 lbs.

Standard extension - 17.7 in.

Standard travel range - 35.4 in.

Control unit

884 mm x 818 mm x 365 mm

100 kg

NEMA 3/12 Enclosure

34.8 in. x 32.2 in. x 14.4 in.

220 lbs.

NEMA 3/12 Enclosure

Probe to control unit bundle

20 m long

3 m long zinc Splash-resistant cover at the probe

Standard travel range - 900 mm

65 ft. long

10 ft. long zinc Splash-resistant cover at the probe

Standard travel range - 35.4 in.

Gas management

Ultra-High-Purity grade components

Inlet pressure up to 206 bar

100% stainless steel flexible line, 30 m long Pressure tested for leak-free operation

Ultra-High-Purity grade components

Inlet pressure up to 3000 psi

100% stainless steel flexible line, 100 ft. long

Pressure tested for leak-free operation

Interested in getting into real-time molten aluminum composition?

Our team will answer all your questions and suggest the best solution for your needs.

Leave your details so our experts can contact you.